<< Back to News

BGW Energy in Poland

ARTICLE

Reflecting on Q2 2025

From new installations and continued team development to exciting customer milestones, we’re focused on progress with purpose. Following our 25th anniversary, the momentum for intentional customer and partnership relations continue – on the road, at the plant, and in every conversation.

Let’s dive in…

Project Updates

ALCO Energy – We’re excited to announce the successful installation of our Whitefox ICE® membrane dehydration system at ALCO Energy Canada (formerly IGPC Ethanol) in Aylmer, Ontario. This project boosts ALCO’s ethanol production capacity by over 50 million liters/year (13.5 million gallons/year) – a 15% increase – while improving efficiency across distillation and dehydration.

This marks Whitefox’s 18th installation and our first in Canada, a key milestone in our North American growth strategy.

“We are honored to partner with ALCO Energy Canada, a company that shares our commitment to improving efficiency and sustainability in the ethanol industry…” — Gillian Harrison, CEO, Whitefox Technologies

Read the full story here.

Lincolnway Energy – In Nevada, Iowa, Lincolnway is wrapping up installation of its Whitefox ICE® system, an important step toward greater efficiency and increased capacity. The system is helping the plant move closer to a major milestone: 100 million gallons of ethanol production.

By targeting water-rich recycle streams, Whitefox ICE® eases load on distillation and dehydration, boosting throughput and energy savings. Commissioning is nearly complete, with strong early results.

A big thanks to the Lincolnway team for being such a collaborative partner. We’re proud to support your path to even greater performance!

How New Tools Are Powering Better Customer Support in the Whitefox Pledge

We’ve expanded our use of Power BI to enhance support for customers through the Whitefox Pledge – a subscription-based program that provides ongoing performance insights and regular support to help plants maximize their Whitefox systems. This tool helps us quickly visualize both real-time and historical plant data: making it easier to spot trends, troubleshoot issues, and provide more informed recommendations.

For Pledge customers, this means:

Maximum productivity at on-site visits

More focused operations reports

Faster issue resolution

Strategic use of engineering hours

This tool streamlines data analysis to deliver smarter, more proactive support – another way we add value through the Whitefox Pledge.

“PowerBI helps us understand what our customers need in real time – whether its optimizing operations or troubleshooting an issue. With clearer data and faster insights, we’re able to step in sooner, solve problems quicker, and keep things running smoothly.”

— Melanie Zimmer, Whitefox Customer Support Team Lead.

Long-Term Performance, Proven Results: CVEC and Whitefox ICE

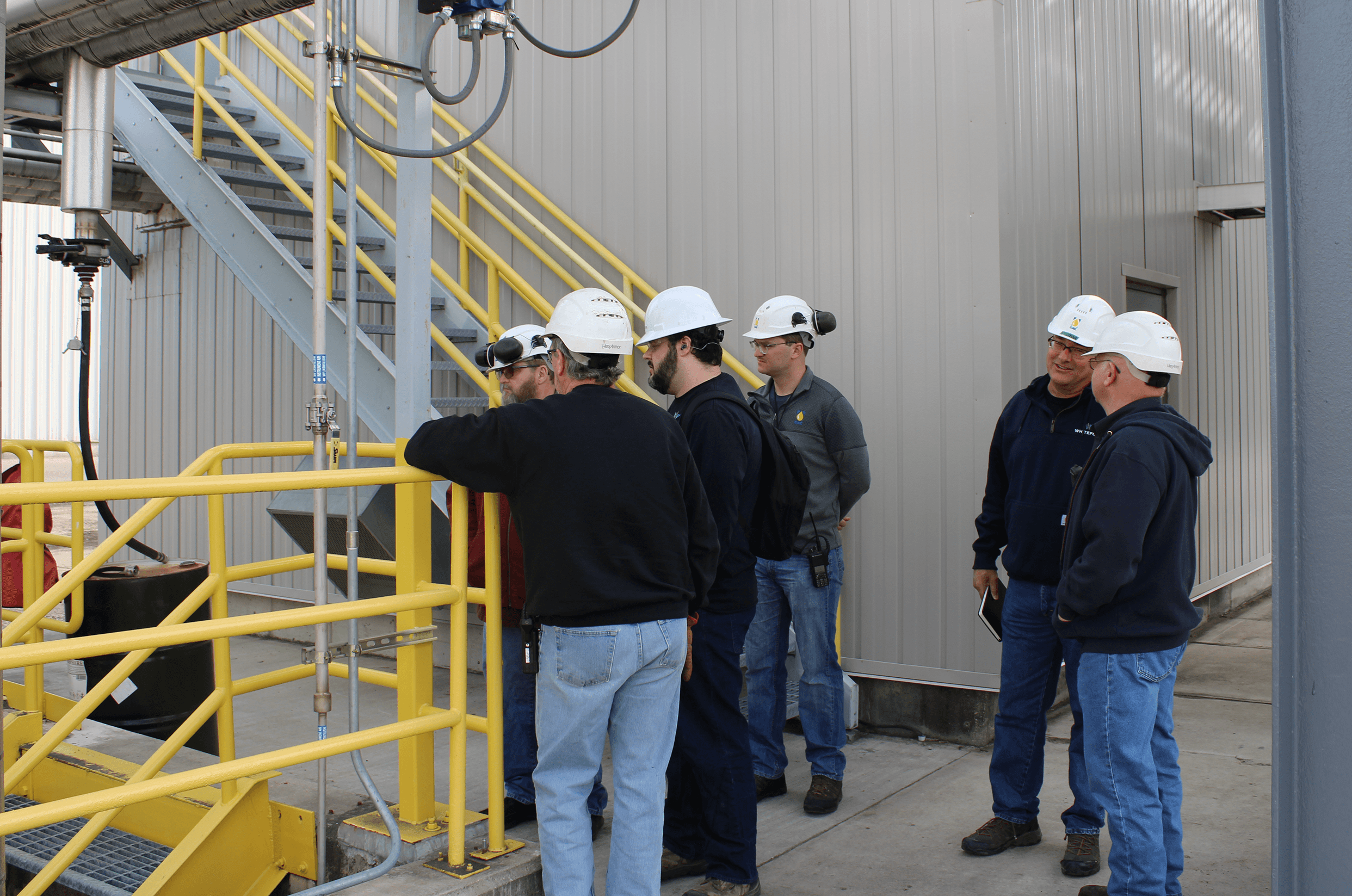

Chippewa Valley Ethanol Company (CVEC) in Benson, Minnesota, has been operating a Whitefox ICE® system since 2019. CVEC holds the distinction of having the longest-running membrane cartridges in the U.S. – a testament to the durability and performance of the system and the CVEC team. Led by CEO Chad Friese, the CVEC team is known for running a smooth, efficient operation that plays a vital role in their local economy and community.

In April, a few members of our U.S. team visited the plant to check in on the system and reconnect with the team. It was great to see how well the system continues to perform and hear firsthand experiences from the operators.

Since commissioning, CVEC has achieved significant performance improvements, including a 13% reduction in water usage and increased production capacity.

“The Whitefox system takes strain off of our distillation and allows us to consistently meet our moisture specs,” said Chad Friese, CEO of CVEC. “It helps us add gallons at the relative cost of energy while keeping our operation stable around moisture requirements.”

Consistent, low-pressure operation has been a key factor in their continued success. CVEC remains a strong example of the long-term reliability, efficiency, and sustainability Whitefox ICE® brings to ethanol plants across the globe.

Ready to optimize like CVEC? Talk to our team today.

Honoring Innovation and Impact

Big news! Our CEO, Gillian Harrison, has been awarded the 2025 Women in Ethanol Award at the Fuel Ethanol Workshop & Expo in Omaha!

“It’s a tremendous honor to receive this recognition from peers I deeply respect in a category with so many amazing women,” said Gillian Harrison. “This award belongs to our entire team, our partners, and the customers who continue to push boundaries with us.”

Meet the Team: Austin Angel

Austin Angel joined Whitefox in January 2024 as a Process Engineer. His strong communication skills and natural connection with customers quickly stood out. In March 2025, he moved into a customer-facing role on our Customer Support Team, and he’s been on the road helping plants ever since.

In his role, Austin supports plant commissioning, sequence testing, operator training, and provides ongoing monitoring and performance insights. Most recently, he worked closely with the team at Lincolnway Energy, helping them bring their Whitefox system online and guiding training efforts.

“I worked in operations at one of Cargill’s ethanol plants for a few years before joining Whitefox, so working in the plant feels like home. It’s been great getting to help customers like Lincolnway get up to speed and see their systems performing well.”

— Austin Angel

Outside the office, Austin’s all about the outdoors, whether it’s hiking, skiing, camping, or running, he’s always on the move.

You might see Austin at an upcoming conference or site visit – feel free to say hi and chat about all thing’s ethanol (or hiking)!

Technical Tips: Why Pressure Control Matters in Membrane Dehydration

In membrane-based dehydration systems, like Whitefox ICE®, controlling pressure is key to system performance and product quality.

The Basics:

Membranes separate water from ethanol when there is sufficient driving force. This comes from feed pressure into the membrane cartridge and vacuum pull on the permeate (which is the water rich stream permeating through the membrane).

Why It Matters:

Better pressure control = stable operations

Stable operations = consistent product quality

Smart pressure adjustments = higher efficiency

For example, if your vacuum system can’t maintain the right pressure on the permeate side, moisture levels can rise. One way to correct this is by increasing pressure on the retentate side, restoring balance and getting you back to spec.

Pressure isn’t the only factor – feed moisture and cooling also play a role – but it’s one of the easiest levers to adjust in real time to optimize performance.

Whitefox News

What 45Z Means for Ethanol Producers

Two major federal policy updates are shaping the future of the US ethanol industry. The proposed RVOs for 2026/2027 signal good news for the industry. At the same time, the passage of the 45Z tax credit into law on July 4 marks a major win for low-carbon ethanol producers.

To stay competitive, plants will need to show carbon efficiency and operational flexibility. Technologies like Whitefox ICE® XL can help producers cut their carbon intensity score by 6–8 points, depending on their baseline – enough to significantly boost eligibility for 45Z credits, which are worth $0.1215 per CI point below 50. That could translate to millions of dollars per year in credits through 2029. ICE-XL targets the most energy-intensive unit operations, dehydration, distillation, and evaporation, helping ethanol plants meet clean fuel goals while maximizing profitability.

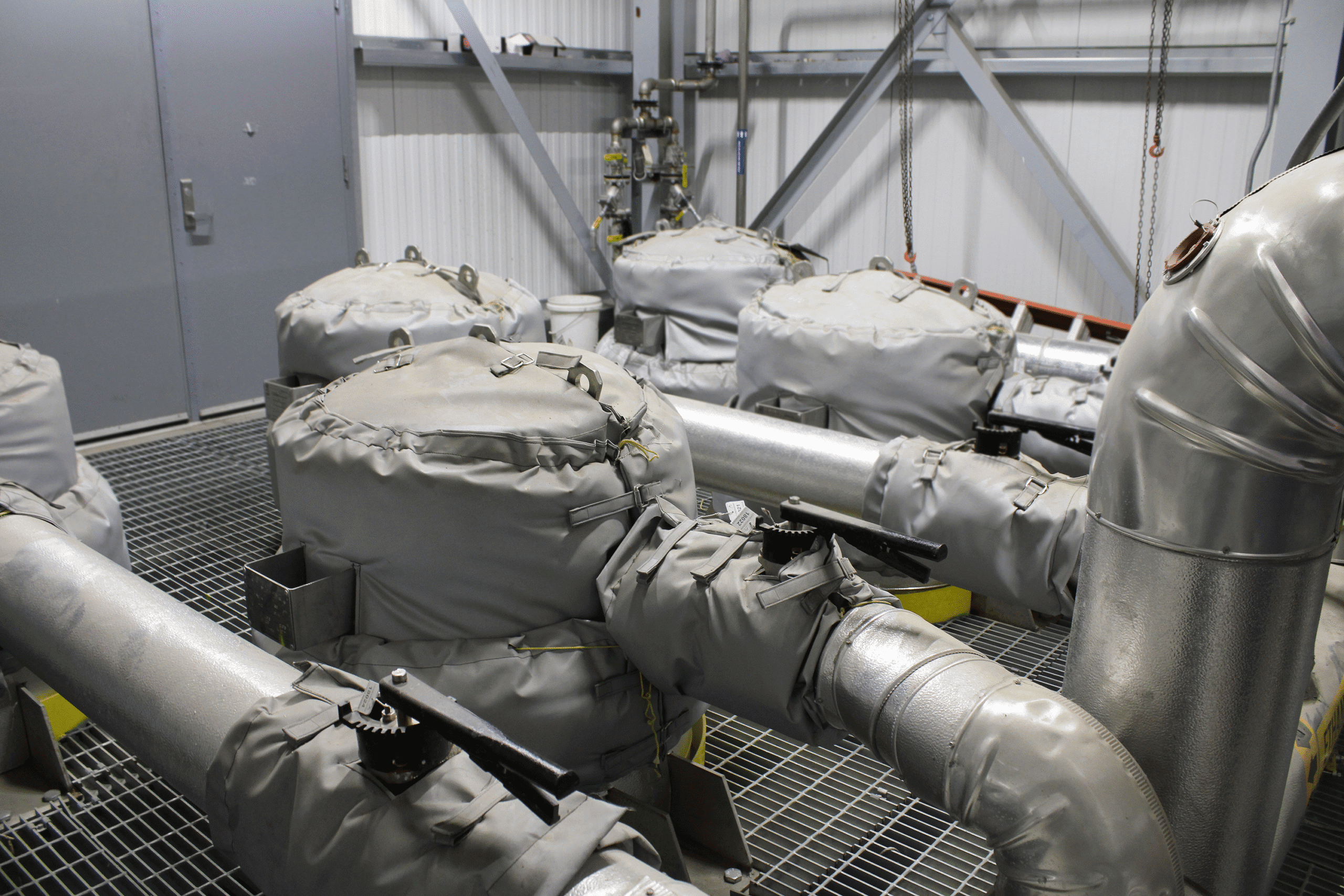

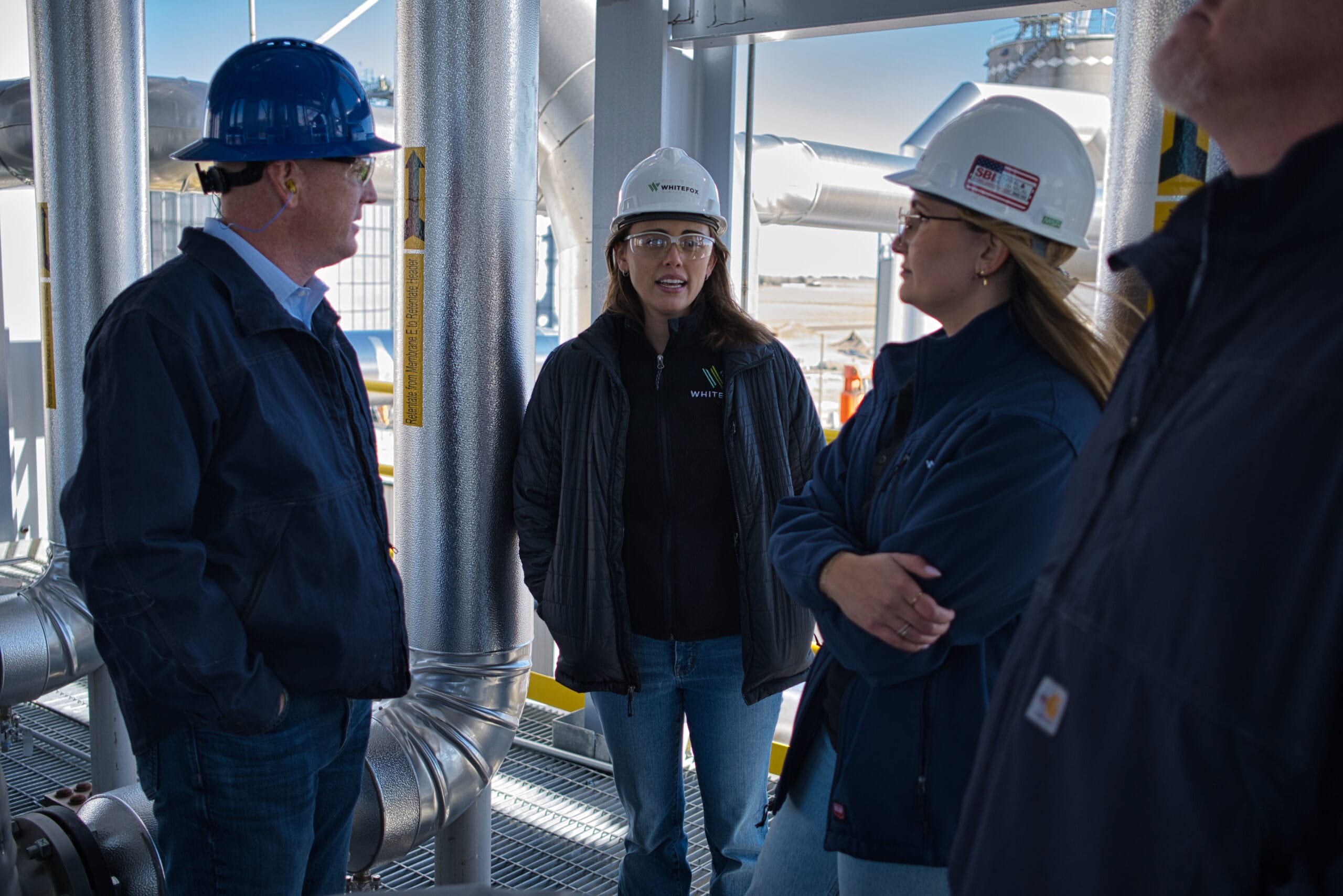

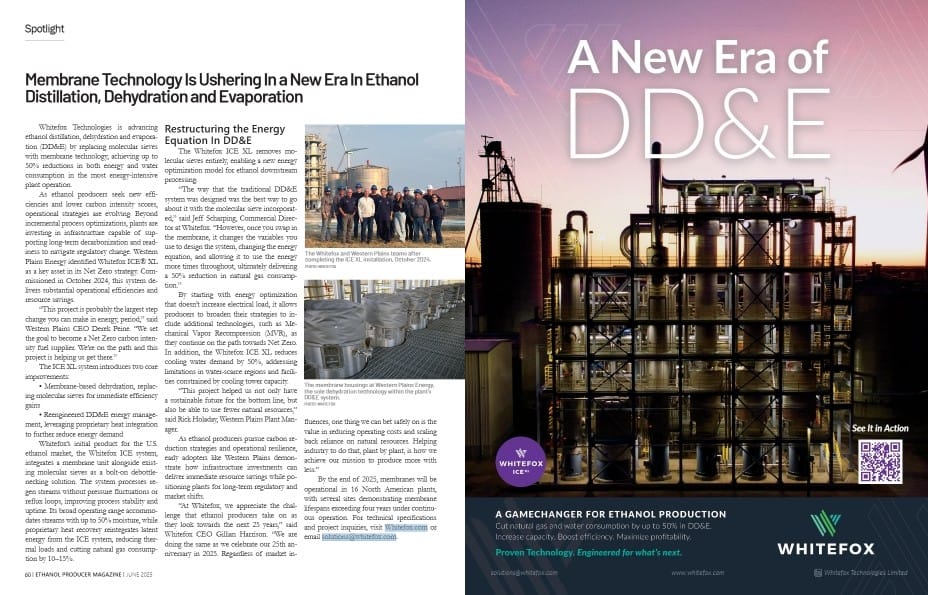

To learn more, check out the Ethanol Producer Magazine article here.

We’re thrilled to be featured in the June issue of Ethanol Producer Magazine, highlighting how Whitefox is shepherding in a new era of DD&E via the Whitefox ICE XL and the transformation it delivers for ethanol production.

Check out the full spotlight and see how we’re helping producers optimize energy and performance. Go to pg. 60!

Read the full article here.

In addition, Whitefox was named #28 on the Top 50 Companies in EnviroTech list, selected from an impressive shortlist of 135. A testament to our ongoing commitment to innovation and environmental performance in the industrial biotech space.

Check out the full list here.

We’re Finalists in Two Categories!

Whitefox Technologies and our CEO, Gillian Harrison, have been named finalists in the Women in Green Business Awards 2025!

- Business of the Year – Whitefox Technologies

- Leader of the Year – Gillian Harrison

With over 450 entries, we’re honored to be recognized for our commitment to sustainability and leadership in the green economy. Thank you for your continued support! Winners will be announced October 8, 2025, in London.

Where We Have Been

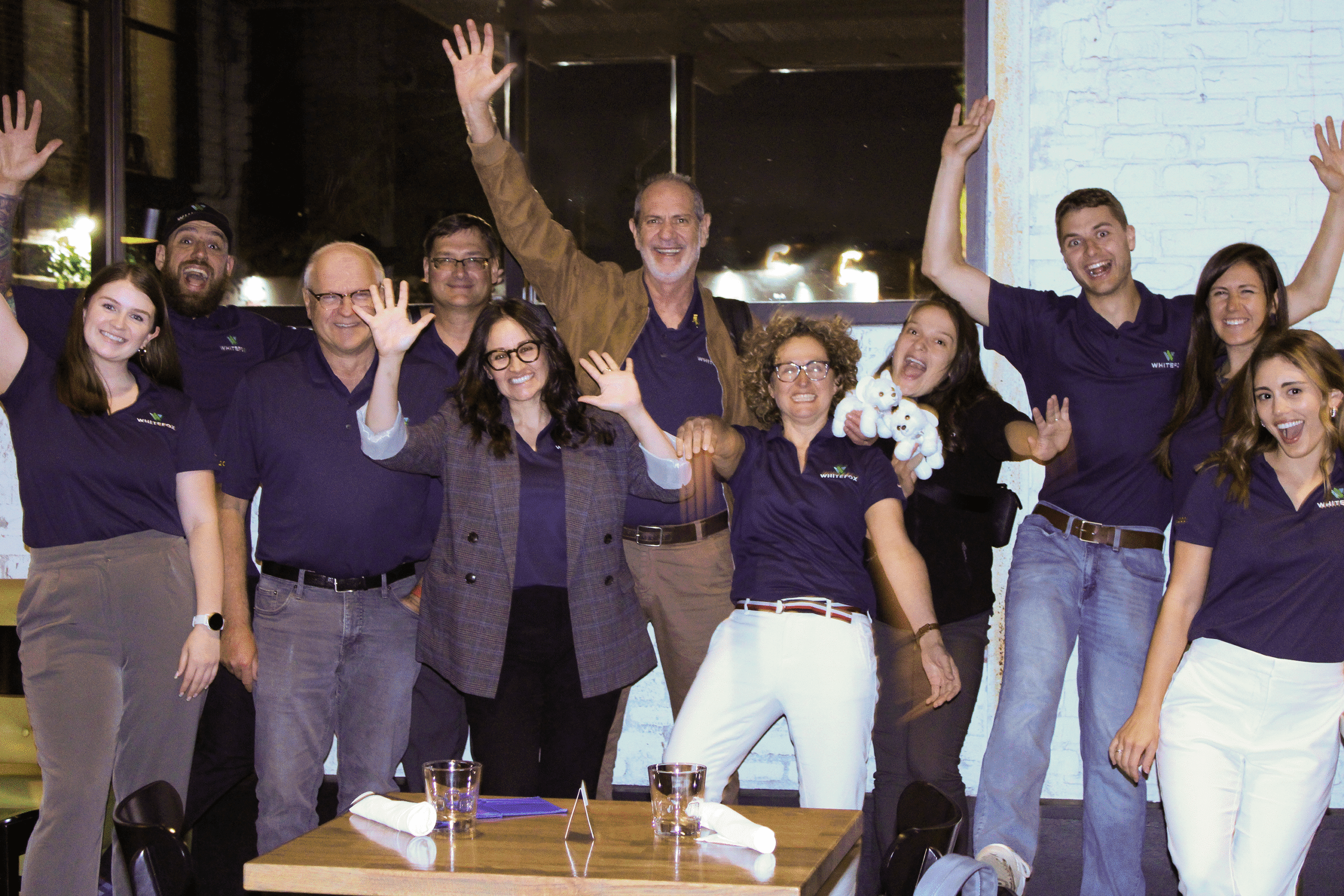

FEW 2025 – Just a few weeks ago, the Whitefox team headed to Omaha for the Fuel Ethanol Workshop & Expo 2025 – and what a week it was! We had a blast reconnecting with friends, meeting new faces, and celebrating 25 years of Whitefox at our Customer Appreciation Event.

Jessica Lopez and Stephan R. Blum, Ph.D., P.Eng. shared insights on dehydration, distillation, and evaporation (DD&E) unit operations and the future of the ethanol industry with membrane technology, while Yelizar Rozenberg and Derek Peine (CEO of Western Plains Energy) took the Innovation Stage to talk about the new Whitefox ICE Installation.

Thanks to everyone who made it such a memorable week. See you in St. Louis!

Want more highlights? Read our full press release here.

Indiana Corn Growers Association’s High Octane Low Carbon Liquid Fuel Summit – Jacqueline Hayes, MBA, Whitefox Business Development Manager, moderated a panel on “biofuels tactics” with colleagues from across the industry, highlighting the strategies that producers can deploy to reduce their carbon intensity scores and qualify to sell ethanol as feedstock into new markets, including SAF and maritime fuel.

During the discussion, she highlighted how technologies like Whitefox help producers strategically reduce their CI scores by reducing steam consumption in the most energy intensive unit operations.

As the year continues, you’ll find the Whitefox team at many key industry events, including:

- Renewable Fuels Nebraska Q3 Meeting – Kearney, NE – Aug. 5 – 6

- ACE Conference – Sioux Falls – Aug. 20 – 22 (Featuring a presentation by Jeff Scharping, Whitefox Commercial Director)

- Iowa Renewable Fuels Association Annual Members Day & Quarterly Board Meeting – Ames, IA – Sept. 3 – 4

- Growth Energy Biofuels Summit – Washington, D.C. – Sept. 8 – 11

- Renewable Fuels Association Annual Meeting – Omaha, NE – Sept. 30 – Oct. 1

Until Next Time…

Thanks for reading! As we wrap up Q2, we’re energized by the momentum, partnerships, and innovation shaping the year so far. We’ll be back soon with more updates, stories, and insights…until then, don’t hesitate to reach out or catch us at an upcoming event. See you on the road!

ABOUT WHITEFOX TECHNOLOGIES LIMITED

Whitefox specializes in technology development and innovation based on its proprietary membrane solutions. Whitefox’s solutions use membrane-based cartridge technology which enables clients to produce ethanol and other chemicals to the highest market standards in the most energy and water-efficient way. With a small carbon footprint, Whitefox provides solutions for all types of alcohols, biofuels, and renewable chemicals in the U.S., Canada, Europe, and South America.